Click HERE to return to the contents page

Click HERE to return to the contents page

Click HERE to return to the contents page

Click HERE to return to the contents page

A Full Electric Vehicle 4WD Type

Translation from English to Estonian

Translation from English to Estonian

Original Link

EVS28

KINTEX, Korea, May 3-6, 2015

International Electric Vehicle Symposium and Exhibition

Danut Gabriel MARINESCU1, Cristian Liviu POPESCU2, Ion

TABACU1,

Viorel NICOLAE1, Florin SERBAN1, Stefan TABACU1,

Ionel VIERU1, Iorga ADRIAN1

1 Automotive Engineering Research Centre, University of Pitesti,

Pitesti, Arges, Romania

2 Renault Technologie Roumanie, Bucharest, Romania.

The paper presents the DUSTER ZERO 4WD concept car, an electric vehicle 4WD type developed within the Automotive Engineering Research Centre, University of Pitesti, in order to create a green and versatile electric all-wheel drive. This concept car was built on the mechanical platform DACIA DUSTER 4WD, by implementing a new electric equipment that containts Renault ZE components already launched on the market for commercialized vehicles. The electric drive, mono-motor type includes a synchronous electric motor type, 44kW, a gears’ reduction with two speeds (L- Low for all terrain and H- High for the road) and a mechanical all-wheel drive system, which allows the driver to choose from three different driving modes: 2WD front-wheel drive for maximum electric energy efficiency, Auto, in which the rear-wheel drive is engaged automatically and Lock, whereby 50 % of torque is consistently fed through the rear axle. The traction battery is lithium-ion technology type, 400 V, 22 kWh for 260 kg battery pack. The performances are: maximum speed: 130 km/h; autonomy (NEDC) (estimated): 160 km; standard charging: 6 to 8 hrs with home WALL BOX Schneider Electric type; fast charging: 0.5 to 1 hr with public and quick charger.

Keywords: Dacia DUSTER 4WD, Electric Vehicle

DUSTER ZERO 4WD (ZERO - Zero Emission ROmanian concept) (figure 1) is an experimental environmentally-friendly vehicle developed during 2013-2014 in the Automotive Engineering Research Centre, University of Pitesti, Romania.

This new concept is developed on the mechanical platform of the Dacia DUSTER 4WD, the low cost crossover car made by the Automobile Dacia- Group Renault, at their plant located near Pitesti city, Romania.

Figure 1: DUSTER ZERO 4WD -Full electric vehicle (ZERO - Zero Emission ROmanian concept)

This study is an academic project and has no connection with the projects or future car models of Dacia-Group Renault.

Unlike the previous concept DUSTER Hybrid E4WD, (named Grand Hamster Electricway 4WD) [1], where only the rear axle was driven in electric mode the DUSTER ZERO 4WD concept is an entirely battery electric vehicle, all-wheel drive.

The new DUSTER ZERO 4WD's overall design is similar to that of the internal combustion-engined version. However there are some features that differentiates it, as follows:

• The front grille is blocked, the cooling radiator is enough with the lower grille area, due to the high efficiency of the electric motor;

• The inscriptions with turquoise lettering: “Full Electric Vehicle”, at the rear side and “Full Electric 4WD” on both sides indicate that it is an electric vehicle; Duster ZERO logo which is present on the roof rails and also on the front side, represents another sign that this vehicle is powered by electricity.

DUSTER ZERO 4WD is a light SUV (Sport Utility Vehicle) developed in order to create a green and versatile Dacia all-wheel drive for the special applications usable in areas with restrictions on pollution.

The electric version of Dacia DUSTER 4WD features the same practical functions as the internal combustion- engined version, i.e. the same carrying capacity and the same high standard of comfort. On top of that, it delivers a silent ride, responsive performance, immediate availability of torque as soon as its starts, automatic transmission, low running costs and, of course, the satisfaction of owning a zero -emissions vehicle in the areas of use.

3 Duster ZERO 4WD Architecture

The electric drive system 4WD concept is a mono-motor type and it includes an electric powertrain placed in front side of the vehicle and a transmission all-wheel drive type.

The traction battery assembly with three stacks is located in the central and rear sides.

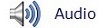

The architecture of the DUSTER ZERO 4WD is presented in figure 2.

Figure 2: Architecture of the DUSTER ZERO 4WD, full electric vehicle, all-wheel drive: 1 Traction battery packs, 2 HV Conductors, 3 Connexion box/Charger, 4 Inverter/DC/DC 14V, 5 Electric motor, 6 Coupling, 7 Reducer with two speed, 8 Front differential, 9 Front drive shafts, 10 Transfer gear box, 11 Propeller shaft, 12 Electric Controlled Coupling, 13 Conical gear, 14 Rear differential, 15 Rear drive shafts

When the driver presses the accelerator pedal, the lithium-ion battery 1 transmits energy to the electric machine 5 via the high voltage conductors 2, the connexion box 3 and the inverter 4.

The front reduction gears have two forward speeds, L- Low, for all terrain and H- High for the good roads. The reverse mode is realized by the electric machine.

The battery charges whenever the vehicle decelerates. When the driver lifts his foot from the accelerator pedal, the vehicle's cinetic energy is recovered by the electric machine 5 (generator mode) which converts it into electric current. The current generated is stored in the traction battery 1.

The electric power-train assembly is located in the front side of the vehicle, in transverse position (figure 3).

Figure 3: DUSTER ZERO 4WD motor compartment

It includes: the Connection Box and the Charger, the Power Electronic Box with the DC/DC converter and the inverter box, the electric machine (the electric motor) and the transmission 4WD type.

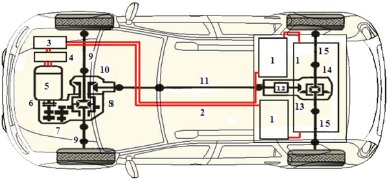

The connection of these components is presented in the figure 4.

Figure 4: The electrical power circuit DUSTER ZERO 4WD

To integrate this assembly in the engine compartment from Dacia Duster 4WD we used a new arrangement of the components, different of the Renault ZE solutions. They are joined by a specific frame mounted on the car body.

The liquid-cooling system for the electric machine inverter and the battery charger is in a closed circuit with the radiator, two pumps (one for the main electric motor and inverter and the second one for the battery charger), and the thermostat and the relief valve. The fan is bi-speed.

4.1.1 Electric Powertrain Components Electric Machine

DUSTER ZERO 4WD is powered by an electric motor, 5AM40 type, made by Continental- Renault which also equips Renault Kangoo ZE vehicle. It is a synchronous electric motor with rotor coil, high speed machine, high power density and high efficiency [2]. Peak power is 44 kW at 1856 - 10500 rpm and the maximum torque is 226 Nm at 480-1856 rpm [4]. To connect the electric machine with the new front gearbox it was necessary to adapt the stator housing in the transmission side. The transfer of the power to the new transmission is made by an original coupling device.

Connexion Box and Traction Battery Charger

This assembly made by LEAR company is placed on the top of the power-train. In the charging mode it receives the energy from the charging socket and distributes it to the traction battery charger. In the traction mode it receives the energy from the traction battery and distributes it to the inverter to the electric motor.

Inverter, DC/DC Converter and Excitation

This assembly made by Continental company, fluid cooling is a powerful electronic for electric machines in hybrid and electric vehicles versions. It is compact in size and weight, and it has a very high power density. The inverter drives the electric machine in motor and generator mode.

The DC/DC Converter converts the electricity from HV traction battery and conventional 14V power net. The output power: up to 3kW.

The Motor Control Unit is made by Continental company. It realizes: the driver demand acquisition; the powertrain torque management; the brake pedal management; the recuperation/regeneration; the HV energy management; the traction battery charge management; the 14V battery charge management; thermal management e.g. heating, air conditioning and pre-conditioning; the E-power-train system cooling (electric water pumps) and communication gateway Central safety management.

4.1.2 Transmission 4WD Type

The new transmission of the DUSTER ZERO 4WD was made starting from the mechanical DUSTER 4WD transmission, internal combustion-engined version. Due to the favourable characteristics of the electric motor the new transmission does not require clutch, gearbox or reverse gear. In this case DUSTER ZERO 4WD can be driven similarly to a vehicle with automatic transmission.

The selector lever (figure 8) has four positions. P: park; R: reverse; N: neutral; D: drive. The drive mode switch is given the command by a cable (for the forward, the neutral and the reverse mode) and the Parking Lock device. The display of the instrument panel (figure 8) shows these modes.

However, to have similar performance as the thermal vehicle, a change was made for a reducer with two speeds. The architecture of this transmission (figure 2) includes: a new coupling motor/gear input shaft 6, a new reducer with two speeds 7, and the classic components: front differential 8, front drive shafts 9, Transfer gear box 10, propeller shaft 11, electric controlled coupling 12, conical gear 13, rear differential 14, rear drive shafts 15.

The new Parking Lock device is mounted in the reducer housing.

The change of the speeds, L- Low, for all terrain and H- High for the roads, is made by a servo-motor controlled by the driver by a button. Depending on the road conditions, similar as the internal combustion-engined version the mechanical all-wheel drive system can provide three different driving modes by another button:

• 2WD, where the transmission is locked into front-wheel drive for maximum electric energy efficiency and maximum autonomy. This mode is used on dry roads with good grip. And the following is indicated on the new instrument panel;

• Auto, in which the rear-wheel drive is engaged automatically. The operating principle “AUTO” distributes the electric motor torque between the front and the rear axles, according to the road conditions and the vehicle speed. This position optimises the road holding. This mode is used on any type of road: dry, snow covered, slippery, etc. This mode is not indicated on the instrument panel and it is not available now;

4WD Lock, whereby 50% of torque is consistently fed through the rear axle. The operating principle “4WD Lock” mode distributes the electric motor torque between the front and rear axles in order to optimise the performance capacity of the vehicle in off-road situations. This mode is used only in extreme driving conditions (mud, steep slopes, sand). This mode is indicated on the new instrument panel.

4.2 Traction Battery and Battery Charging System

The traction battery, lithium-ion, air cooled contents two stacks of 12 modules each and one stack of 24 modules serial coupled: the first stacks are located in a central position beneath the rear seats and the second one is located above the rear axle. This new architecture was chosen to boast the same carrying capacity as the internal combustion-engined version.

The capacity of DUSTER ZERO 4WD’s traction battery is 22kW/h and the weight is 260 kg. In addition to the modules package the battery box includes: the internal cooling system, the electrical circuit computer and connection box, the BMS box, the signal wiring “low voltage” and the general contactor.

An energy recovery system enables the battery to be charged when the car decelerates.

DUSTER ZERO 4WD is charged via a socket located in the front side of vehicle (figure 5).

Figure 5: Front socket of the DUSTER ZERO 4WD

The actual variant (without additional heating) has a secondary socket located in the lateral rear side, behind the flap of the fuel tank (figure 6).

Figure 6: Rear socket of the DUSTER ZERO 4WD

It will be possible to charge the battery of DUSTER ZERO 4WD in one of the following two ways:

• A household mains supply (10A or 16A, 220V) which will fully charge the battery in between six and eight hours. This method is particularly suited to vehicles which are charged during the workday or at night, since it allows owners to benefit from the off-peak rates available in certain countries;

• At fast charge stations using a 32A 400V supply which enables the battery to be charged in approximately 30-60 minutes.

The standard charging is made with home WALL BOX Schneider Electric type and the fast charging with public and quick charger.

Table 1: Power levels for charging (230V)

10 |

220V |

2.2 |

|

16 |

3.5 |

||

32 |

400V |

7.0 |

4.3 Chassis

4.3.1 DUSTER ZERO 4WD’s Suspension

In order to adapt the DUSTER ZERO 4WD to the new weight distribution, the suspension has been revised.

The front axle is an independent pseudo Mac Pherson type, with hellicoidal springs, hydraulic telescopic shock absorbers and anti-roll bar. The front suspension setting is softer, since electric motors are lighter than all the internal combustion engines available for DUSTER 4WD.

The rear axle is an independent pseudo Mac Pherson type with lower pulled arm with hellicoidal springs, hydraulic telescopic shock absorbers and anti-roll bar. Meanwhile, the rear suspension has been revised to cope with the heavier weight, due to the presence of the traction battery.

4.3.2 DUSTER ZERO 4WD’s Steering

Another important change to the vehicle was adapting an electric power steering system, variable rate, column-assist type. This system, a brushed DC motor was integrated in the steering column; the motor was located in the passenger compartment.

Compared with the traditional hydraulic steering systems, with hydraulic pump or electric motor and pump (“powerpack”) mounted on the Dacia cars, the Electric Power Steering system offers the driver assistance directly and it has the advantages of energy economy, handiness, easy adjustment, less noise and waste, oil pollution and the working principle of ESP system.

4.3.3 DUSTER ZERO 4WD’s Braking

The braking system is similar to the diesel version and includes: ventilated discs on the front axle with 280 mm disc diameter, drum in the rear axle 9 inches diameter, Anti-lock Braking System (ABS) Bosch 8.1, Electronic Brake force Distribution (EBD), Emergency Brake Assist (EBA) and ESC (Electronic Stability Control).

For the assist system a new vacuum pump HELLA, electric type was installed in the engine compartment behind the 12V auxiliary battery.

4.4 DUSTER ZERO 4WD’s Interior

The range management is a key factor when it comes to electric vehicles, and has taken significant steps to make this aspect as straightforward and efficient as possible.

Figure 7: The DUSTER ZERO 4WD cockpit

A specific dashboard display (figure 7) has been adapted to ensure that the driver is kept informed about the remaining battery charge and the operational range:

• A gauge alongside the speedometer indicates how much battery charge remains;

• An “Econo”-meter provides the driver with an indication of energy consumption based on a system that employs three colors: light blue depicts normal use, dark blue reveals optimal energy use, while red informs the driver when he is using excessive energy in a way that will have an negative effect on the vehicle's operational range;

• The speedometer needle moves across a turquoise arch;

• The trip computer's functions are adapted to the needs of electric vehicles. It displays the remaining range and the remaining battery energy (kWh), as well as real-time and average energy consumption.

An Eco Mode function is available on DUSTER ZERO 4WD. Activating this function limits the operation of the air conditioning and the heating system and it results in increasing the range by up to 10%.

4.5 DUSTER ZERO 4WD’s Climatisation

Similar to the Renault electric vehicles DUSTER ZERO 4WD is equipped with a HVAC system with an electric compressor AC DENSO and an electric heating device.

The system with a specific architecture serves to cooling / heating the interior of the car and cooling /heating the traction battery. The liquid circuit is equipped with one radiator for the interior climatisation and one radiator for the external battery climatisation and the two pumps.

When the car is plugged in, the driver can programme pre-conditioning system, pre-heating or pre-cooling of the cabin.

In order to increase the cooling and heating efficiency, and cuts down on heat entering or leaving, thus also reducing the air-conditioning’s power consumption the following measures were taken:

• The thermal insulation of the roof with aluminium foil and a hollow layer;

• The thermal insulation of the windows with anti UV foil, turquoise color;

• The rear window was replaced with a Rear Hatch Glass to lower the access surface of luggage compartment (figure 8).

Table 2: Technical data DUSTER ZERO 4WD

4315 |

|

2000 |

|

2673 |

|

1560 |

|

1567 |

|

210 |

|

30º |

|

Ventral angle |

23º |

36º |

|

1500 |

|

1850 |

|

400 |

|

1570 |

|

350 |

|

5 |

|

10.44/10.76 |

|

3.3 |

|

160 |

|

Top speed (km/h) capped electronically |

130 |

DUSTER ZERO 4WD (ZERO - Zero Emission ROmanian concept), the full electric Dacia 4WD vehicle was built on the mechanical platform DACIA DUSTER 4WD, by implementing a new electric drive with Renault ZE components already launched on the market for commercialized vehicles.

DUSTER ZERO 4WD concept includes the innovative solutions: 4WD Electric Drive with two speeds; a specific dashboard display with specific EVs board computer; an electric power steering system, variable rate, column-assist type, a new HVAC system adapted for the passenger compartment and traction battery.

The project will be finalised on the end of the 2015.

Figure 8: The Rear Hatch Glass of the DUSTER ZERO 4WD

This project has been performed in the

Automotive Engineering Research Centre,

Alternative Propulsion System & Renewable

Energies laboratory. We benefited from the help

offered by RENAULT TECHNOLOGIE

ROUMANIE, LEAR ROMANIA, SCHNEIDER

ELECTRIC ROMANIA to whom we express our gratitude.

[1] D.G. Marinescu et. al., A Plug-in Hybrid Diesel-

Electric Vehicle, EVS26 Los Angeles,

California, May 6-9, 2012.

[2] A., Vignaud, H., Fennel, Efficient Electric

Powertrain with Externally Excited Synchronous

machine without Rare Earth Magnets using the

Example of the Renault System Solution. Vienna

Motor Symposium, April 27. 2012.

[3] A., Teyssot. Battery key parameters and their

impact on EV application, SHC Day,

Gothenburg, May 7th 2012.

Danut Gabriel Marinescu,

He got the degree in Automotive in

1984 and Ph.D in 2002. He worked in

the Dacia R&D Centre in the

powertrain field. Since 1992 he has

worked at the Automotive and

Transportation Department within the

University of Pitesti. In the present he

is Assoc.Prof., currently lecturing on Alternative powertrain discipline and

Director of the Automotive

Engineering Research Centre

dan.marinescu@upit.ro

Ion Tabacu,

He got the degree in Automotive in

1972 and the PhD in 1986. He works

at the Automotive and Transportation

Department of the University of Pitesti

since 1972. In the present, he is

Professor at Automobile Mechanical

Design discipline.

ion.tabacu@upit.ro

Viorel Nicolae

He got the degree in Automotive in

1985 and the PhD in 2000. Since

1993 he works at the Automotive and

Transportation Department of the

University of Pitesti. In the present, he

is Professor at Automobile Fabrication

and Reparation discipline.

viorel.nicolae@upit.ro

Florin Serban

He got the degree in Automotive in

1988 and the PhD in 1999. Since

1997 he works at the Automotive and

Transportation Department of the

University of Pitesti. In the present, he

is Assoc.Prof. at Automotive

Mecatronic discipline.

florin.serban@upit.ro

Stefan Tabacu

He obtained an engineer degree in

Automotive in 1999 and Ph.D. in

2002. Since 1999 he works at the

Automotive and Transportation

Department of the University of

Pitesti. In the present, he is Assoc.prof.

currently lecturing on Vehicles

Structures and Structural Analysis.

stefan.tabacu@upit.ro

Ionel Vieru

He got its degree in Automotive in

1985 and its PhD in 2001. Since 2002

he works at the Automotive and

Transportation Department of the

University of Pitesti. In the present, he

is assoc.prof. at Computer Aided

Design discipline

ionel.vieru@upit.ro

Adrian IORGA,

PhD student in the

Automotive and Transportation on

Department, Faculty of Mechanics and

Technology, University of Pitesti